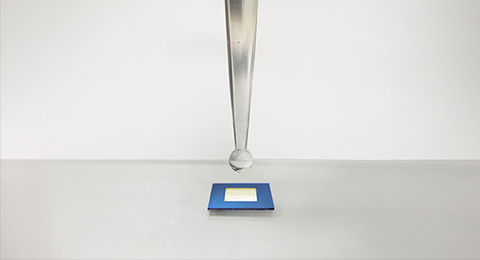

two professors used the silicon nitride membrane independently developed and produced by YW MEMS (Suzhou) as the carrier in their research, and patterned the Pd coating on the flat and clean silicon nitride film by magnetron sputtering.

Biologicalsample support membrane in STXM technology

TEM sampler holder support membrane

Apply tolong sequence, low cost, single molecule high throughput DNA sequencing technology.

Real-time dynamic observation of nano_samples in liquid environment.

Customized MEMS technology solution achievemore RD innovation.

Clear imaging

100-level clean environment preparation

100% inspection

Super support

Pressure tolerance (PSI): 60

Stress: 250Mpa

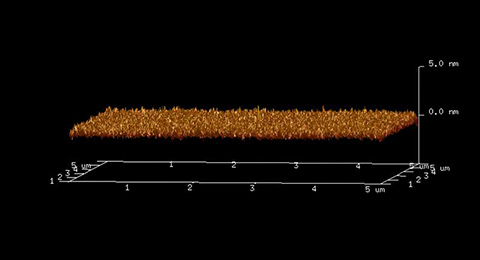

Surface roughness: <0.3nm

Thickness consistency: <5%

Mature technology

Piece by piece inspection

Quality assurance

two professors used the silicon nitride membrane independently developed and produced by YW MEMS (Suzhou) as the carrier in their research, and patterned the Pd coating on the flat and clean silicon nitride film by magnetron sputtering.

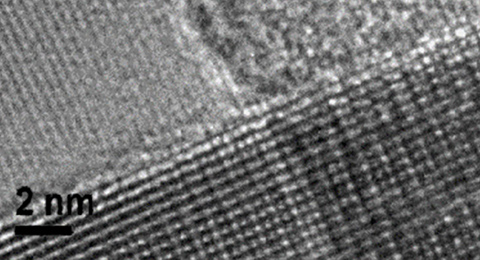

Silicon Nitride (SiN) TEM window grids have a strong, flat, uniform silicon nitride membrane and are widely used as a stable viewing platform for TEM, SEM, Cryo-EM, AFM, Raman, XRD, and other equipment.Standard sizes range from 10 nm to 200 nm, but YW MEMS can respond quickly to customized design requirements and are very popular.

silicon nitride membrane

synchrotron radiation silicon nitride membrane window

silicon nitride membrane

silicon nitride membrane

silicon nitride membrane windows

silicon nitride membrane

silicon nitride membrane window

Synchrotron Radiation Facility

silicon nitride membrane

silicon nitride membrane

Recently, Professor Wanjun Jiang research group, State Key Laboratory of Low Dimensional Quantum Physics and Quantum Information Frontier Science Center, Department of Physics from Tsinghua University, took the lead in realizing perpendicular magnetic anisotropy in rare earth permanent magnet SmCo5 thin film materials through interface optimization and nano film preparation technology. The researc

Xunbiao Zhou, Xiaobin Liao, Xuelei Pan, Mengyu Yan, Liang He, Peijie Wu, Yan Zhao, Wen Luo, Liqiang Mai...

Nano Energy Volume 83, May 2021, 105748

Yongcai Qiu, Genlan Rong, Jie Yang , Guizhu Li, Shuo Ma, Xinliang Wang, Zhenghui Pan, Yuan Hou, Meinan Liu...

Advanced Energy Materials Volume 5, Issue 23

Zidong Wang, Minghua Guo, Heng-An Zhou, Le Zhao,Teng Xu, Riccardo Tomasello, Hao Bai, Yiqing Dong...

Nature Electronics Volume 3, pages672–679(2020)

two professors used the silicon nitride membrane independently developed and produced by YW MEMS (Suzhou) as the carrier in their research, and patterned the Pd coating on the flat and clean silicon nitride film by magnetron sputtering.

Silicon Nitride (SiN) TEM window grids have a strong, flat, uniform silicon nitride membrane and are widely used as a stable viewing platform for TEM, SEM, Cryo-EM, AFM, Raman, XRD, and other equipment.Standard sizes range from 10 nm to 200 nm, but YW MEMS can respond quickly to customized design requirements and are very popular.

silicon nitride membrane

synchrotron radiation silicon nitride membrane window

silicon nitride membrane

silicon nitride membrane

silicon nitride membrane windows

silicon nitride membrane

silicon nitride membrane window

Synchrotron Radiation Facility

silicon nitride membrane

silicon nitride membrane

Recently, Professor Wanjun Jiang research group, State Key Laboratory of Low Dimensional Quantum Physics and Quantum Information Frontier Science Center, Department of Physics from Tsinghua University, took the lead in realizing perpendicular magnetic anisotropy in rare earth permanent magnet SmCo5 thin film materials through interface optimization and nano film preparation technology. The researc

Xunbiao Zhou, Xiaobin Liao, Xuelei Pan, Mengyu Yan, Liang He, Peijie Wu, Yan Zhao, Wen Luo, Liqiang Mai...

Nano Energy Volume 83, May 2021, 105748

Yongcai Qiu, Genlan Rong, Jie Yang , Guizhu Li, Shuo Ma, Xinliang Wang, Zhenghui Pan, Yuan Hou, Meinan Liu...

Advanced Energy Materials Volume 5, Issue 23

Zidong Wang, Minghua Guo, Heng-An Zhou, Le Zhao,Teng Xu, Riccardo Tomasello, Hao Bai, Yiqing Dong...

Nature Electronics Volume 3, pages672–679(2020)